Before, we discussed here "considering things during earth excavation of UGWT". After that we wrote about "how to make UGWT's bottom slab". In that post, we discussed general procedure of making UGWT's bottom slab. We didn't show how to place reinforcement in UGWT's bottom slab. In today's post we will discuss about that.

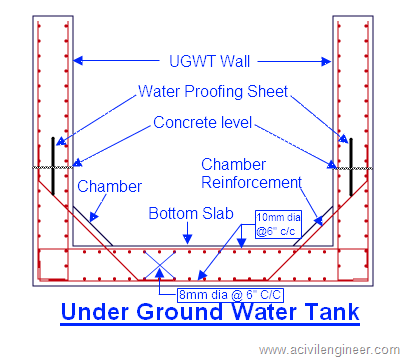

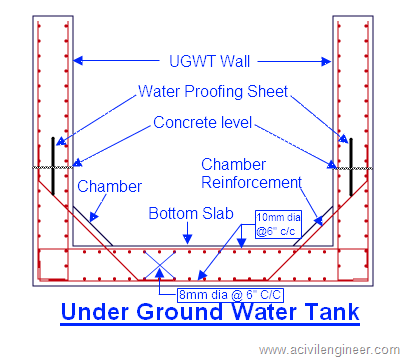

We have a drawing which shows the size and spacing of steel bars for UGWT. But it's not showing how to place steel. See the image below.

Did you face this problem before? If you faced, this post will give you a solution. If you not faced, yet you should read this post to learn.

Now the core question is - which steel bar should go bottom and in which direction?

Anatomy of drawing: In the above image (that is our drawing), we have 10 mm dia bar @ 6" c/c and 8mm dia bar @ 6" c/c. Obviously 10 mm dia bar is the main bar and 8 mm dia bar is the binder. We know the size of our water tank that is 30'x7'. The water tank section doesn't make any sense that which is placed in short direction of water tank and which is long direction.

In this situation follow the rule discussed below:

As we know the main steel goes along short direction. So we can say the above section of water tank is the short section.

Now lets start placing steel bars. First place 10 dia bars along short direction and place 8mm dia bars on 10 mm dia bar along long direction as specified spacing in the drawing. Now fix the bars with binding wire. Make “L” bend (in construction we call it mutum) in both side of steel bar. After this process we have just finished one net. But our slab reinforcement is double net. So we have to make another net by following same procedure above. But this net is reverse of 1st net.

For making 2nd net, place 8 mm dia bars along long direction and place 10mm dia bars on 8mm dia bars along short direction. Give “L” bend in both ends of bars. As our bottom slab thickness is 10" and clear cover is 3" so “L” bend length should be below 4".

Our bottom slab reinforcement is ready but we have to place vertical wall reinforcement before casting the bottom slab.

Place vertical wall reinforcement as specified dia and spacing. Don't forget to make dowel in the wall's vertical bar. Also place the chamber reinforcement which is 8 mm dia bar shown in the drawing.

Now our UGWT's bottom slab is ready for casting.

How to Place reinforcement in UGWT's bottom slab

We have a drawing which shows the size and spacing of steel bars for UGWT. But it's not showing how to place steel. See the image below.

Did you face this problem before? If you faced, this post will give you a solution. If you not faced, yet you should read this post to learn.

Now the core question is - which steel bar should go bottom and in which direction?

Anatomy of drawing: In the above image (that is our drawing), we have 10 mm dia bar @ 6" c/c and 8mm dia bar @ 6" c/c. Obviously 10 mm dia bar is the main bar and 8 mm dia bar is the binder. We know the size of our water tank that is 30'x7'. The water tank section doesn't make any sense that which is placed in short direction of water tank and which is long direction.

In this situation follow the rule discussed below:

As we know the main steel goes along short direction. So we can say the above section of water tank is the short section.

Now lets start placing steel bars. First place 10 dia bars along short direction and place 8mm dia bars on 10 mm dia bar along long direction as specified spacing in the drawing. Now fix the bars with binding wire. Make “L” bend (in construction we call it mutum) in both side of steel bar. After this process we have just finished one net. But our slab reinforcement is double net. So we have to make another net by following same procedure above. But this net is reverse of 1st net.

For making 2nd net, place 8 mm dia bars along long direction and place 10mm dia bars on 8mm dia bars along short direction. Give “L” bend in both ends of bars. As our bottom slab thickness is 10" and clear cover is 3" so “L” bend length should be below 4".

Our bottom slab reinforcement is ready but we have to place vertical wall reinforcement before casting the bottom slab.

Place vertical wall reinforcement as specified dia and spacing. Don't forget to make dowel in the wall's vertical bar. Also place the chamber reinforcement which is 8 mm dia bar shown in the drawing.

Now our UGWT's bottom slab is ready for casting.

0 comments:

Post a Comment